Fluidic Components Welding

Sensitive parts such as fluid-carrying components can be welded together precisely, permanently, firmly and above all contamination-free.

The areas of application are diverse, whether gases or liquids, the main thing is that the weld is tight and meets the requirements. The laser welding processes used are based on the design of the components and their production requirements. Laser welding is particularly suited to the requirements of microfluidics. Here, the areas between the fluidic channels must be hermetically sealed without contaminating the channels themselves. Complex structures with long weld seams and varying sizes can be ideally welded with mask welding - a mixture of contour and simultaneous welding. With this technique, welding times can be reduced many times over compared to contour welding. Compared to other joining methods such as adhesive bonding, laser welding saves production steps, material and storage costs.

Fluidic components with less complex welding structures are often welded with other laser welding processes such as contour welding or quasi-simultaneous welding. Especially if process control is needed during the welding process. Simultaneous welding is used less frequently, but has its justification in the production of simple welding geometries, such as a ring, in mass production.

Gas analysis system

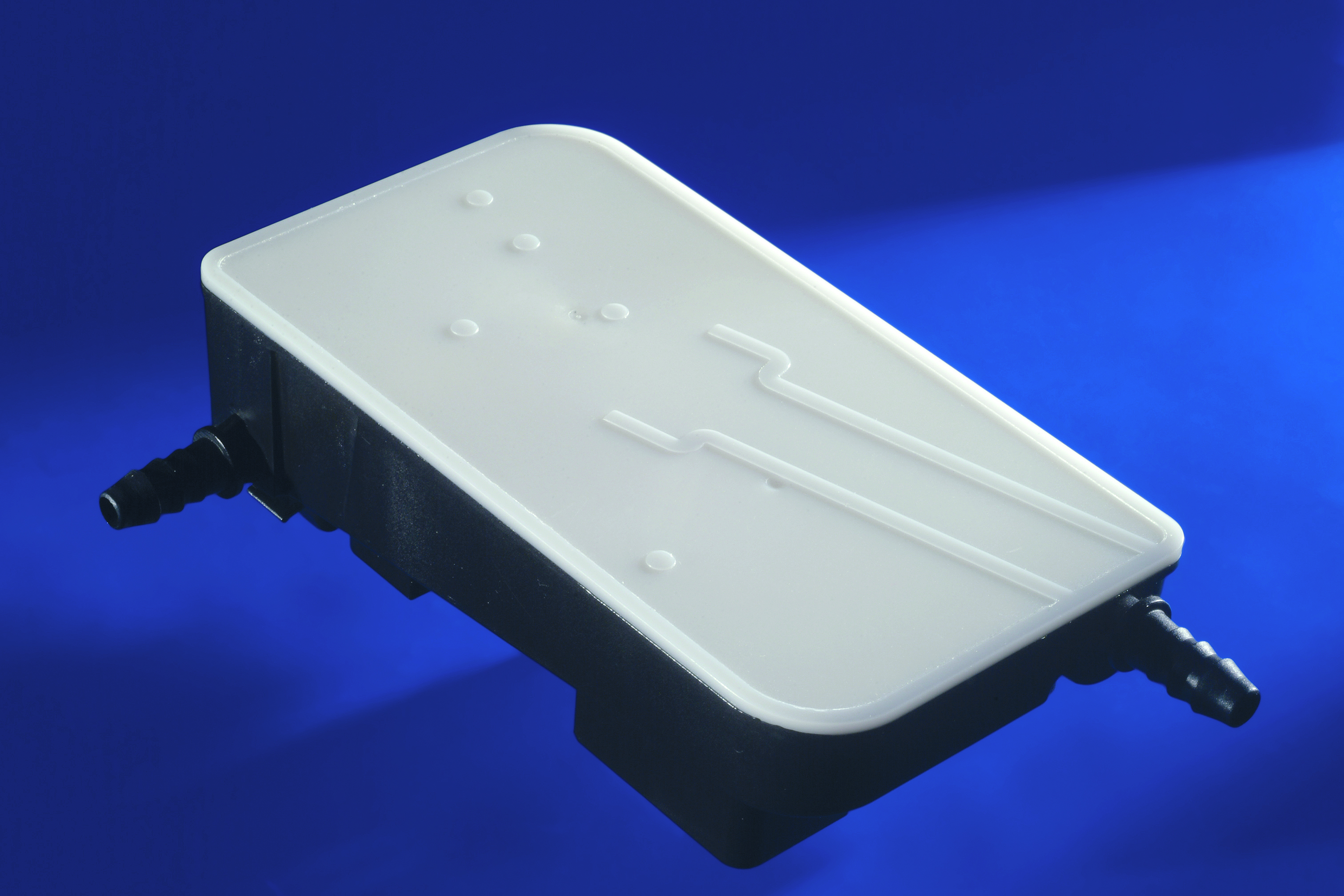

Gas analysis systems are used in various applications to determine elements and their concentrations.

The gas is fed into a cassette where it is divided into several channels for analysis. The channels must be hermetically sealed. Contamination-free laser welding is an ideal and fast welding process, which has proven itself in practice. A weld seam length of several meters can be welded in seconds.

Medication dosage

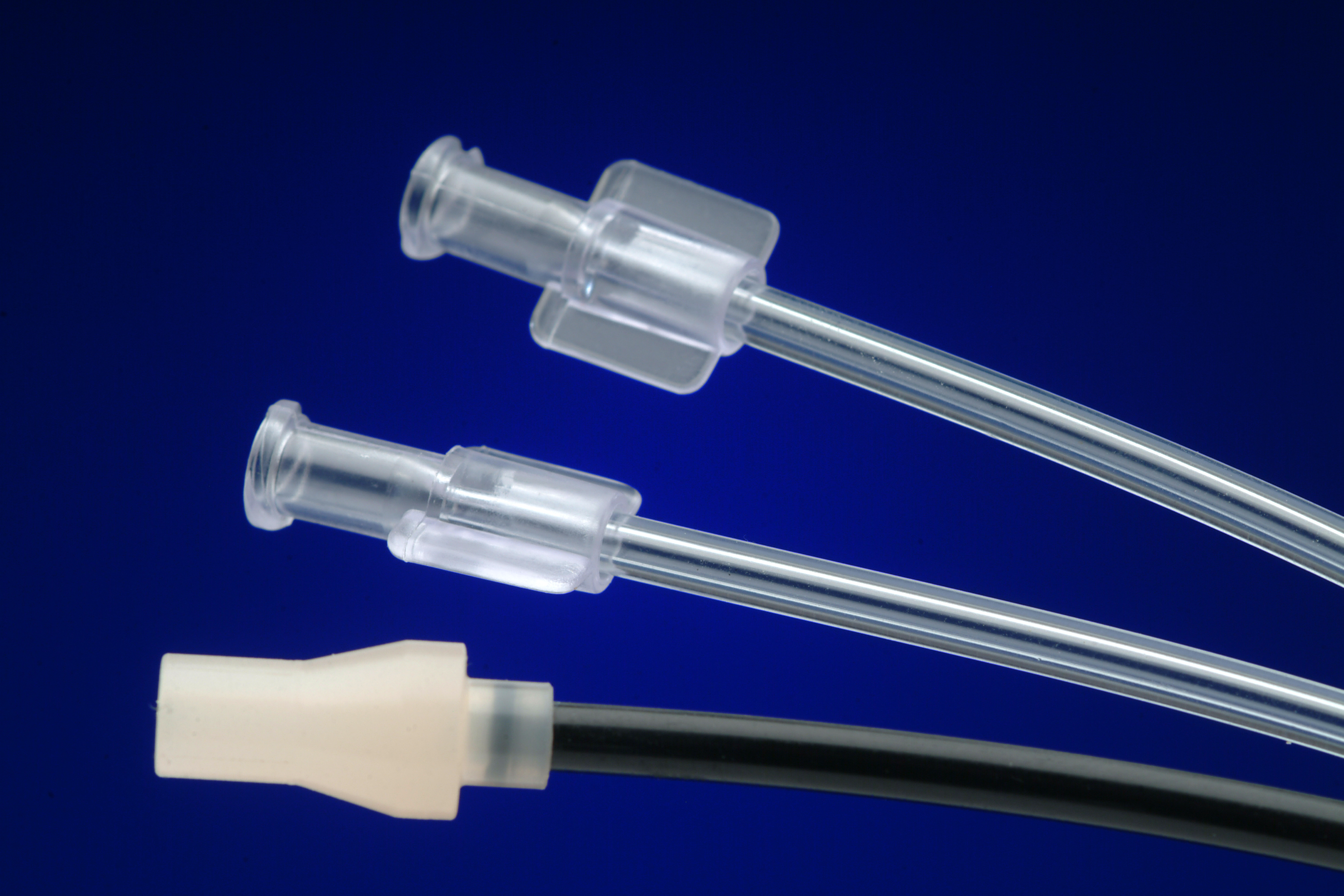

Laser welding of plastics is a very clean and reliable joining method.

The thermal and mechanical load on the components is small compared to other welding processes and therefore very suitable for the medical industry. Infusion pumps are only one of many examples in this category. It is important that the channels through which the drugs are transported are hermetically sealed without contaminating them.

Fluidic systems in the automotive industry

In the automotive industry, laser welding of plastics is a process that has established itself due to the high reliability of producing continuous weld seams.

The Liquid Vapor Separator (LVS) is a good example in this. The LVS is installed between the fuel tank system and an activated carbon filter, and it separates liquid fuel from the vapor. For the sake of the environment, the fuel is fed back into the tank, while the gases are filtered and released into the environment.

Blood analysis in medical technology

Fluidic components are also used in blood analysis to divide the blood into different channels and reservoirs. The fluid-carrying areas must be defined, separated from each other and sealed off. The areas between the channels and reservoirs must therefore be joined tightly and evenly.

In the case of the cartridge shown, an absorber is applied to the surface of the components before welding. This can be applied individually and converts the laser power applied into heat energy only locally. This means that two transparent components can also be welded with the laser.

Complete range of accessories

-

View productsBASIC M

View productsBASIC MThe BASIC M laser welding system from Hymson Novolas AG is based on a modular block building system.

-

View productsNOVOLAS WS-AT

View productsNOVOLAS WS-ATThe NOVOLAS™ WS-AT is a universal modular laser welding system and a manual workstation that can be provided with expansions and accessories for versatility.

-

View productsMAXI

View productsMAXIMAXI is a modular, universally applicable laser welding system form Hymson Novolas, which is particularly suitable for large components. The system can be additionally extended by housing attachments. In addition to the standard version, extensions with rotary table and transfer belt are available to increase the throughput. As an alternative to the servo axes, the system can be equipped with a 6-axis robot. This significantly increases the contour welding flexibility, especially in combination with the GLOBO Optics.

-

View productsINLINE WELDER

View productsINLINE WELDERThe Inline Welder from Hymson Novolas is a laser welding system for integration into industrial production lines. In the laser-safe processing cell, 2D contours can be welded with the Scanner Optic from Hymson Novolas on a working area of max. 250×250 mm.

-

View productsBASIC S

View productsBASIC SThe BASIC S is an air-cooled laser system designed for integration into production lines and manufacturing cells. Due to its consistently modular design, the laser system can be configured very well for different requirements.